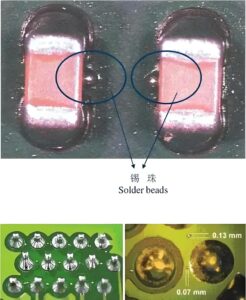

The problem of solder balls in SMT processing affects product quality. It is necessary to start from multiple aspects such as solder paste printing, reflow soldering process, solder paste quality, PCB board design, equipment and environmental management, optimize process parameters, select high-quality solder paste, improve design and strengthen management to reduce the generation of solder balls and improve processing quality and efficiency.

1、 Reasons for the formation of tin balls

There are various reasons for the formation of tin balls, including:

Solder paste printing problem: The solder paste printing is too thick or uneven, resulting in excessive solder paste residue around the solder joint, which forms solder balls during reflow soldering.

Improper reflow soldering process: insufficient preheating, welding temperature too high or too low, heating speed too fast or too slow, can all cause solder ball problems.

Unreasonable PCB board design: design defects such as too close pad spacing and poor shape of pad openings can also increase the risk of solder ball formation.

Solder paste quality issues: Excessive metal content, large particles, poor fluidity, or impurities in solder paste may promote the formation of solder balls.

Equipment and environmental issues: Equipment vibration, high air humidity and temperature, static electricity on the workbench, and other factors may also affect the formation of solder balls.

2、 Methods to prevent the formation of solder balls

Optimize solder paste printing process: Ensure that the opening size of the template is slightly smaller than the contact area of the solder pad to avoid excessive solder paste. Reasonably set the printing pressure and scraper speed to ensure that the solder paste is evenly distributed on the solder pad, avoiding edge collapse and overflow. Maintain the cleanliness and accuracy of printing machines, steel mesh, and other equipment to reduce uneven distribution of solder paste caused by equipment problems.

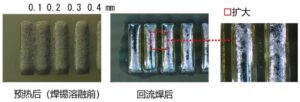

Fine control of reflow soldering process: Ensure that the solvent in the solder paste evaporates sufficiently to avoid splashing caused by excessive solvent during the soldering process. According to the characteristics of solder paste and the design of PCB board, set the welding parameters reasonably to ensure that the solder joints melt evenly and do not overheat. Avoid rapid melting and splashing of solder paste surface caused by too fast heating speed, and also prevent uneven temperature caused by too slow heating speed.

Choose high-quality solder paste: Choose solder paste with moderate metal content, small particles, and good fluidity to reduce solder ball problems caused by poor solder paste quality. Ensure that the solder paste is stored under refrigeration conditions, fully thaw and stir evenly before use to prevent water vapor from entering the solder paste. Avoid using the same batch of solder paste for a long time to prevent deterioration and the formation of solder balls.

Improve PCB board design: Reasonably design the pad spacing to avoid solder paste sticking to each other during the soldering process due to being too close. The solder pad opening designed with anti solder beads reduces the overflow of solder paste during the soldering process.

Strengthen equipment and environmental management: Ensure stable operation of equipment on SMT production lines and reduce solder paste splashing caused by vibration. Maintain appropriate air humidity and temperature, reduce static interference, and create a stable working environment for SMT processing.